Top quality thermo wood kiln

sucess guaranteed

Experience the ultimate in wood treatment technology with our state-of-the-art high temperature wood thermal modification kiln. Designed for versatility and efficiency, our kiln offers dual heating options: electric heating or thermal oil boiler heating, allowing you to choose the best heat source for your needs.

Equipped with advanced PLC automatic control and an intuitive, user-friendly HMI screen, our kiln ensures seamless operation and precision. Achieve superior results with ease and elevate your wood treatment process to new heights.

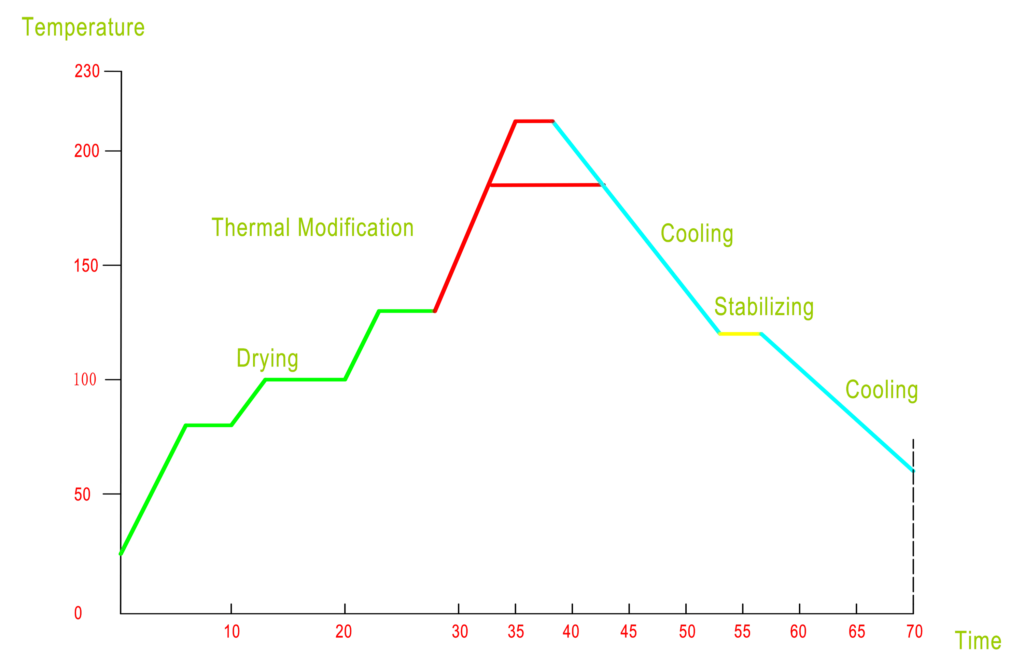

Thermal modification chart demo

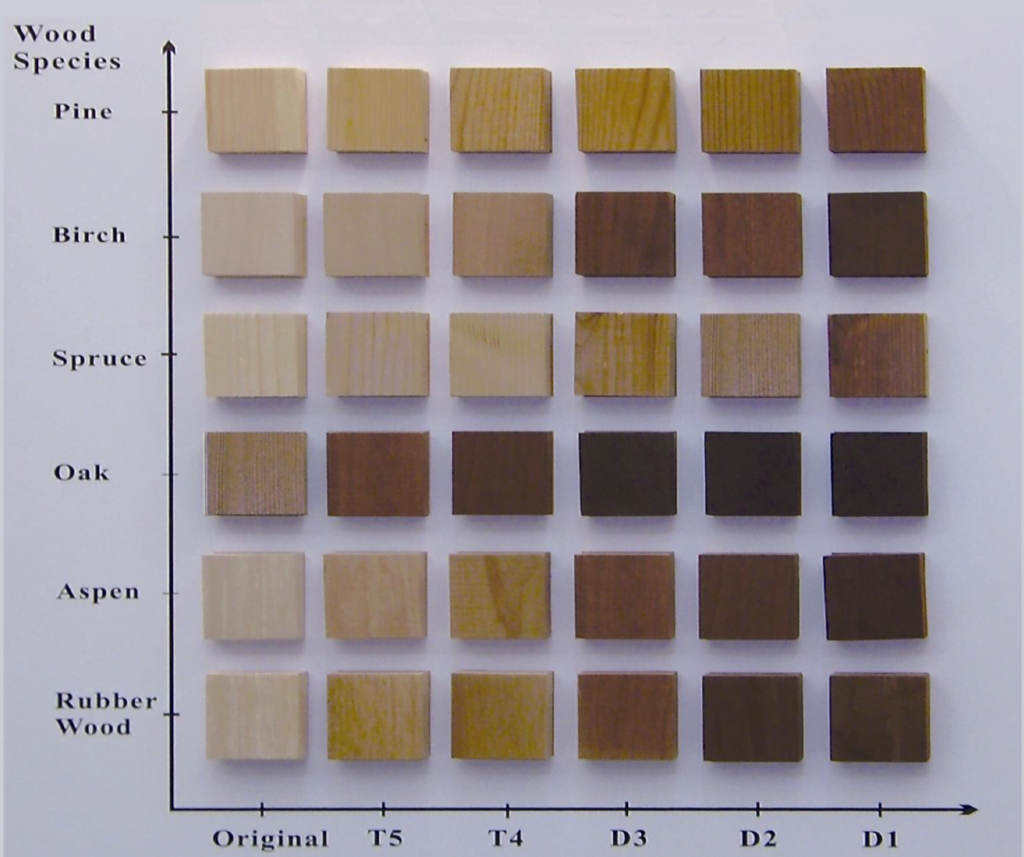

Colors of some thermally modified woods

Key points

Modification temperature

Indoor applications: 160 to 200℃

Outdoor applications:200 to 230℃

Thermal modificaiton cylcle time

About 3 days (water cooled model)

M.C. after thermal modfiication

M.C. : 4 to 6%

Kiln Capacity

For container loading: Max. 62cbm (stacking size)

Max. made at present: 120cbm (stacking size)

Kiln Shape

Cylinder (round) or cubic (squre)

Heating Method

Thermal oil: electric heating or thermal oil boiler

Benefits of thermal modification

Deep Treatment

High-Temperature

Color Control

Transfers temperature to deeper layers, ensuring comprehensive treatment beyond the surface.

Physically enhances wood stability, minimizing susceptibility to cracking and warping.

Real-time observation of the modification process and status.

Ease of Processing

Physical Effects

Aesthetically Pleasing

High-temperature treatment facilitates easier sanding, grinding, carving, and cutting.

Achieves complete degreasing, desugarization, degumming, insecticidal, and anti-termite properties.

Simple, gorgeous, uniform, and adjustable in depth.

Green

Weather Resistant

Materials can be modified

Chemical additive-free, low carbon, purely physical treatment.

Enhances wood’s weather resistance, providing physical resistance to mold and decay.

Suitable for all solid wood products, plywoods, wooden boards.