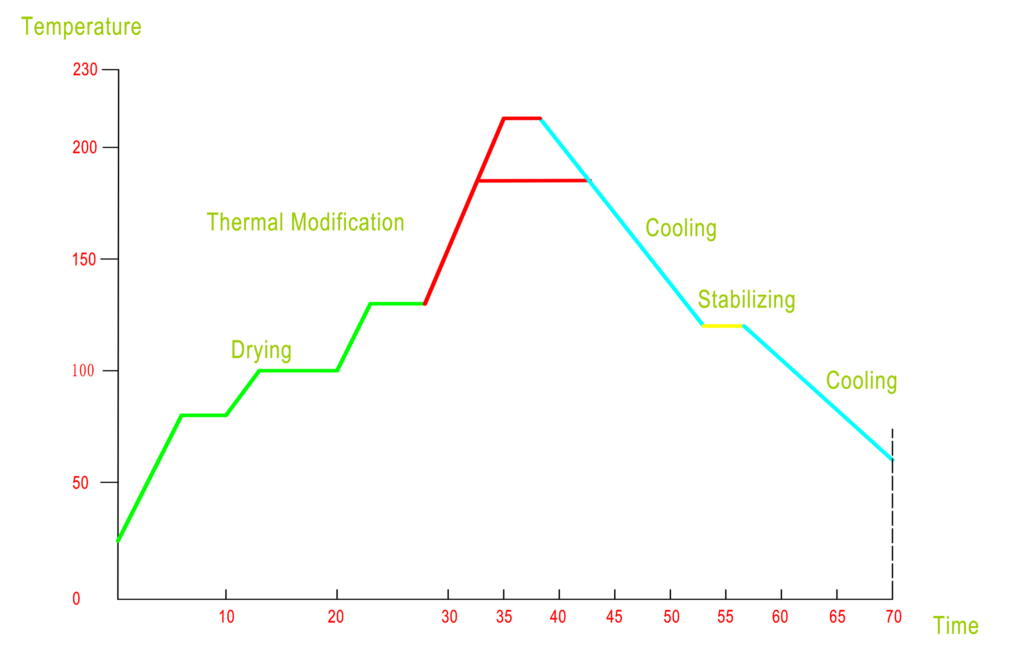

Thermowood, also known as -thermo treated wood, is a type of wood that has been enhanced for durability and stability through a special thermo treatment process. This process alters the wood’s chemical structure, making it more resistant to decay, fungi, and pests. Thermowood is also known for its dimensional stability, meaning it is less likely to warp, swell or shrink with changes in humidity. It’s an environmentally friendly choice as the treatment process uses no chemicals. Due to its unique properties, Thermo wood is commonly used in cladding, decking, and other outdoor applications

Our thermowood kiln is an innovative and high-performance solution designed to enhance the quality of your woods. It operates on a fully automatic and intelligent system, which can be easily managed by a single person. Thermo wood kiln is equipped with an independent sensor detection system that is complemented by an HMI screen, offering clear display of parameters.

The thermowood kiln incorporates a multi-species benchmarking database, ensuring precise matching requirements are met. It is built from high-quality materials, guaranteeing a robust and durable main body. What sets our thermo wood kiln apart is its special structural design and development, which not only simplifies tasks but also conserves energy.

Our thermowood Kiln offers customization of the heat source and working volume based on site conditions. Its entire working process is physical and does not use any chemical additives, ensuring that the woods remains purely natural and environmentally friendly. Moreover, it enables real-time observation of the timber color to achieve perfection.

Safety is our priority, and the kiln is equipped with a safety alarm system to swiftly prevent and eliminate potential hazards. With its deep treatment capabilities, our thermo wood kiln transfers temperature to deeper wood layers, ensuring comprehensive treatment beyond the surface. It physically enhances wood stability, minimizing susceptibility to cracking and warping.

The thermowood kiln offers the ease of processing, with high-temperature treatment facilitating easier sanding, grinding, carving, and cutting. It also achieves complete degreasing, desugarization, degumming, insecticidal, and anti-termite properties.

Our thermowood kiln is aesthetically pleasing, simple, gorgeous, uniform, and adjustable in depth. It is suitable for both indoor and outdoor applications, and is perfect for all solid wood products, plywoods, and wooden boards. We even offer comprehensive services from design and production to installation, training, and after-sales support by a dedicated team of professionals.

Kiln tank shapes: square (cuboid) & round (cylinder)

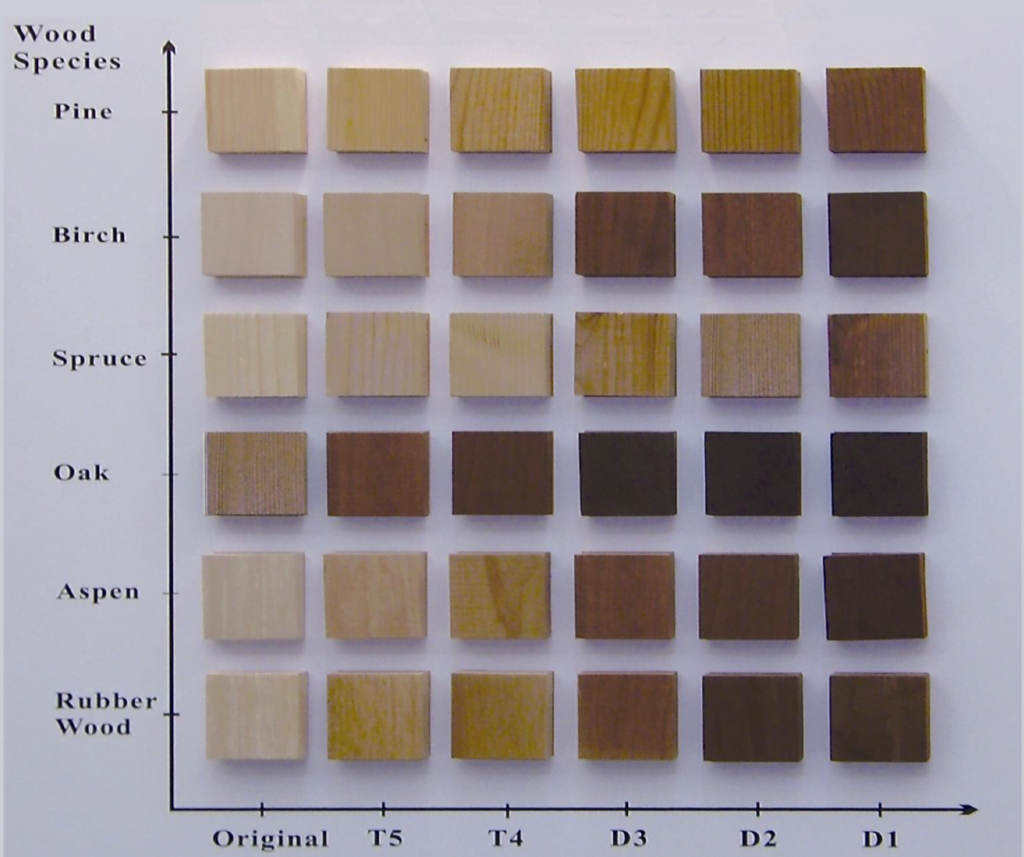

Colors of some thermo wood species

Specs of thermowood kilns

| Model | ETM-5R-ABT | ETM-10R-ABT | ETM-15R-ABT | ETM-20R-ABT | ETM-30R-ABT | ETM-45S-ABT | ETM-60S-ABT |

|---|---|---|---|---|---|---|---|

| Shape | Round (cylinder) | Round (cylinder) | Round (cylinder) | Round (cylinder) | Round (cylinder) | Square (cubic) | Square (cubic) |

| Stacking Capacity | 4.6cbm | 9.802cbm | 15.08cbm | 20.358cbm | 31.104cbm | 45.36cbm | 62.208cbm |

| Stacking Size (mm) | 3200 *1200*1200 | 5200*1300*1450 | 8000*1300*1450 | 10800*1300*1450 | 10800*1600*1800 | 10800*2100*2000 | 10800*2400*2400 |

| No.s of Fan Motors | 3 | 4 | 6 | 8 | 10 | 8 | 8 |

| Power Required | 35kw | 40kw | 55kw | 75kw | 120kw | 155kw | 165kw |

| Steam Volume | 10kg/h | 13kg/h | 13kg/h | 17kg/h | 25kg/h | 25kg/h | 34kg/h |

| Container Required | 20GP | 20GP | 40HC | 40HC | 40FR | 40FR | 40FR |

| Loading Method | End-opening rail type | ||||||

| Heating Medium | Electric heating thermal oil (Thermal oil boiler type can be custom made) | ||||||

| Equipment Body | Inner layer: stainless steel; external layer: steel reinforcement; aluminum silicate and rock wool combination insulation layer; external high-quality metal packaging. | ||||||

| Control System | Automatic controller (HMI screen, PLC, remote control supported); temperature sensor module combination system; pressure sensor module combination system; power distribution cabinet and its electrical components, etc. | ||||||

| Heating circulation system | Motor; aluminum alloy fan; active shaft and accessory parts; electric heater; piping, etc. | ||||||

| Humidification system | Stainless steel steam spray pipe; valve; solenoid valve. | ||||||

| Cooling system | Blower; electric valve. | ||||||

| Automatic inlet and outlet system | Loading trolley; kiln outside inlet and outlet tracks; electric transport control device | ||||||

| Automatic drainage system | Electric valves; piping and water release devices. | ||||||

All thermo wood kilns can be custom made as per customer’s requirement.

Email: [email protected]

WhatsApp: +8618132079385